Oilzapper

One of the biggest and most frequent threats for any oil refinery is oil sludge. There are 23 refineries in India and all create toxic waste. Estimates suggest that about 400,000 tonnes of petroleum sludge is generated every year. At present, refineries have to construct polymer-lined pits with a special leachate collection system to prevent the dumped sludge from leaking into the earth and groundwater. A pit costs about 10 million Indian rupees and each refinery needs several such pits. With more refineries being set up, space is always a constraint. What's more, a pit gets filled up in three to four years

One of the biggest and most frequent threats for any oil refinery is oil sludge. There are 23 refineries in India and all create toxic waste. Estimates suggest that about 400,000 tonnes of petroleum sludge is generated every year. At present, refineries have to construct polymer-lined pits with a special leachate collection system to prevent the dumped sludge from leaking into the earth and groundwater. A pit costs about 10 million Indian rupees and each refinery needs several such pits. With more refineries being set up, space is always a constraint. What's more, a pit gets filled up in three to four years

Oilzapper Intervention

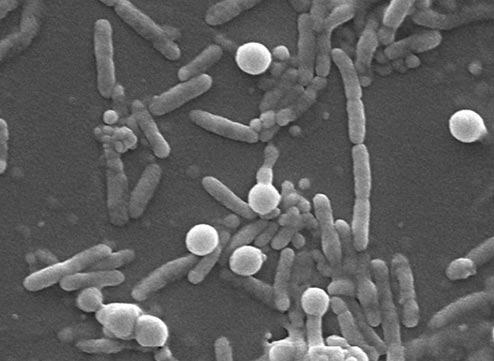

After seven years of research work sponsored by Department of Biotechnology, Government of India and subsequently funded by ONGC, HPCL, BPCL, IOCL, CHT and TERI, the Microbial Biotechnology laboratory at TERI has developed an efficient bacterial consortium that degrades crude oil and oily sludge very fast. This bacterial consortium was developed by mixing four bacterial strains, which could degrade aliphatic, aromatic, asphaltene, and NSO (nitrogen, sulphur, and oxygen compounds) fractions of crude oil and oily sludge. Crude oil and oily sludge degrading efficiency of the developed Oilzapper bacterial strains was tested under laboratory conditions and field conditions.

A microbial consortium was developed from four bacterial strains. These strains were obtained from hydrocarbon-contaminated sites using enrichment methods. The microbial consortium developed was immobilized with a suitable organic carrier material, which is an environment-friendly, biodegradable product. The survivability self-life of the consortium in the immobilized condition was determined and was found to be 3 months at ambient temperatures. The immobilized culture was put into sterile polythene bags and sealed aseptically and transported to the place of requirement. This immobilized bacterial consortium trade name is Oilzapper.

The site was tilled thoroughly to mix the oily sludge uniformly with the soil and oilzapper applied into it. The land was tilled again and watered to maintain proper aeration and moisture levels. The solid sludge material was tilled at regular intervals to facilitate faster degradation.

Effectiveness

Scientists say that 1010 CFU/KG of Oilzapper today can degrade a ton of sludge in a matter of 3-4 months.

How does Oilzapper Work?

There are five different bacterial strains that are immobilized and mixed with an organic material. This mixture of four bacteria is called Oilzapper. Oilzapper feeds on hydrocarbon compounds present in crude oil and the hazardous hydrocarbon waste generated by oil refineries, known as Oil Sludge and converts them into harmless fatty acid and water. The Oilzapper is neatly packed into sterile polythene bags and sealed aseptically for safe transport. The shelf life of the product is three months at ambient temperature. The technique was used successfully and already bioremediated more than 1.5 Million tons of oil soaked soil and oily sludge.

Packaging of Oilzapper at Fermentation Technology Research Centre (FTRC) in sterile condition

Full scale study bioremediation and restoration of oily waste pit in Oil Field of Middle east country at Petromasila, Yemen